Diamond Tooling

SlideMAG Metal Bond Tooling

Bartell Global‘s line of SlideMAG Premium Metal Bond Diamond Tooling has been designed with the busy contractor and rental house in mind: the product line is streamlined, the selection of options is simple and color-coded, and the tooling itself is long-lasting, high-quality, and easy to use. Featuring SlideMAG — the best fastening system in the industry!

PCD Removal Tooling

For effective removal of various coatings, such as epoxy and polyurethane, hardened glues and mortar.

Specialty Tooling

For aggressive cutting & profiling of concrete surfaces, the removal of mastics, and other specialized needs.

iShine Evolution Resin Bond Tooling

Move seamlessly from low-grit metal bond diamonds, to Hybrid Resin diamonds for honing, and then high-grit Standard Resin to achieve a high-gloss polish.

STREAMLINED

We cut through the clutter to cherry-pick a smaller simplified collection of products that tackles a wide range of grinding & polishing jobs.

PROVEN TECHNOLOGY

Our tooling line is the result of decades of research, testing, and contractor feedback.

VERTICAL INTEGRATION

By taking the manufacturing under our own roof, we can now directly control the innovation, quality, and overall integrity of the tooling products we offer.

HIGH ROI

Exceptional quality, productivity, and long-life adds up to better ROI

Introducing... our new line of Metal Bond Diamond Tooling

What is Diamond Tooling?

Diamond tooling is comprised of manufactured industrial diamonds set in a matrix — solid material that suspends and secures the diamonds in place as they interact with the concrete dust produced in the grinding & polishing process. The hard diamonds scratch the concrete, separating fine concrete particles from the surface, creating the abrasive dust that in turn wears down the matrix, exposing more diamonds as you progress, which continue cutting into the floor.

The design of the matrix material is where the magic happens. It is most often made from a proprietary blend of metal alloys, or molded resin, in an infinite spectrum of innovation, chemistry, and physics.

The goal is to find the “sweet spot” by balancing the hardness of your diamond bond with the hardness of the concrete you are working with, to achieve effective cutting or polishing at a pace that is fast enough to be productive, but not so fast that you are burning through your valuable tooling quicker than necessary.

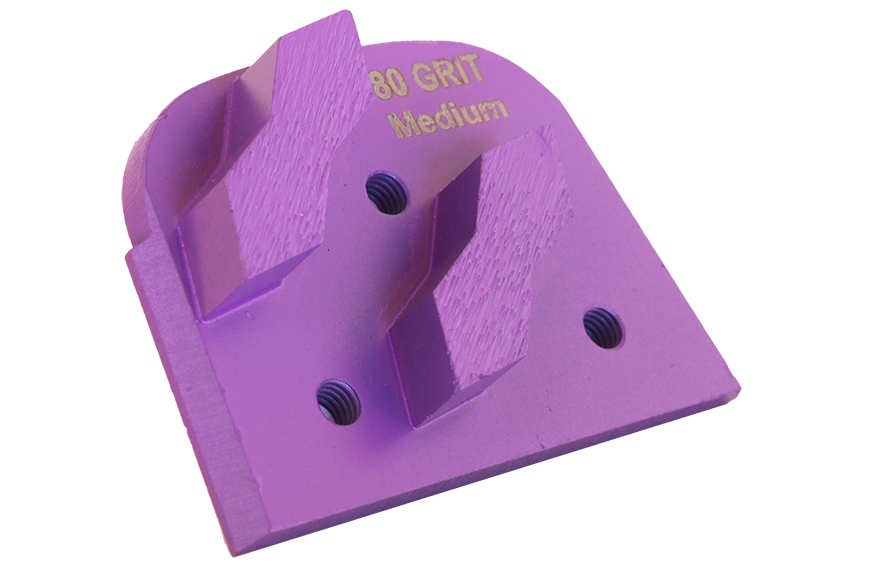

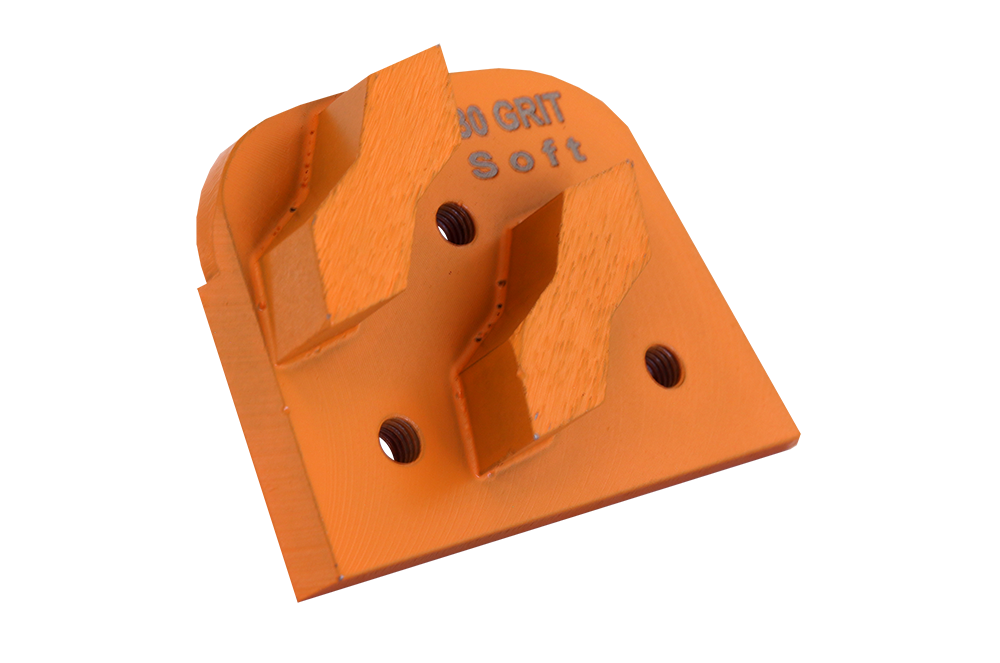

Metal Bond Tooling

Coarse grits For rough grinding and profiling of concrete surfaces

The primary line of metal bond tooling offers a simple and streamlined collection of:

- Three color-coded bond choices:

PURPLE – for use on Soft to Medium concrete

ORANGE – for use on Medium to Hard concrete

GREEN – for use on Hard to Very Hard concrete - Four GRITS: 16, 25, 40, 80

- Two segment shape options: Single or Double

In addition to the standard grinding tooling, we have developed the WHITE series specifically for the removal of a wide range of coatings (adhesives, mastics, mortar, epoxy, etc).

Finally, we have the BLACK series, featuring specialty tooling for when only the most aggressive approach will get the job done.

Resin Bond Tooling

Finer grits for the later stages of polishing concrete to a high-gloss

Our new Resin Bond diamonds transition seamlessly from grinding to polishing, with several options to choose from:

- HYBRID Resins in the mid-range grits (50–400) for either WET or DRY use.

- STANDARD Resins are offered in the higher grits (400–3000) for the final rounds of high-gloss polishing.